Building an innovative and robust domestic advanced packaging ecosystem

SHIELD USA, a collaboration led by ASU and Deca Technologies, advances the goals of the CHIPS and Science Act by working to restore U.S. semiconductor technology leadership and strengthen national security.

As part of the National Advanced Packaging Manufacturing Program SHIELD USA has been funded with $100 million (over five years) from the National Institute of Standards and Technology as part of the CHIPS R&D program and administered by the U.S. Department of Commerce.

SHIELD USA supports a robust domestic microelectronics packaging ecosystem through development of leap ahead technologies – focused on molded core organic substrates – through research, testing and qualification of new materials, processes and equipment.

Accelerates R&D and commercial deployment through technology transfer and licensing to enhance U.S. manufacturing capabilities.

Strengthens domestic supply chains to enhance national security and economic resilience by developing and scaling proven processes, materials and equipment.

Expands microelectronics workforce and research capacity by upskilling and reskilling workers through ASU’s educational resources and training programs.

Supports U.S. leadership in semiconductor packaging by building a sustainable, domestic advanced packaging infrastructure to support viable supply chains that meet global demand.

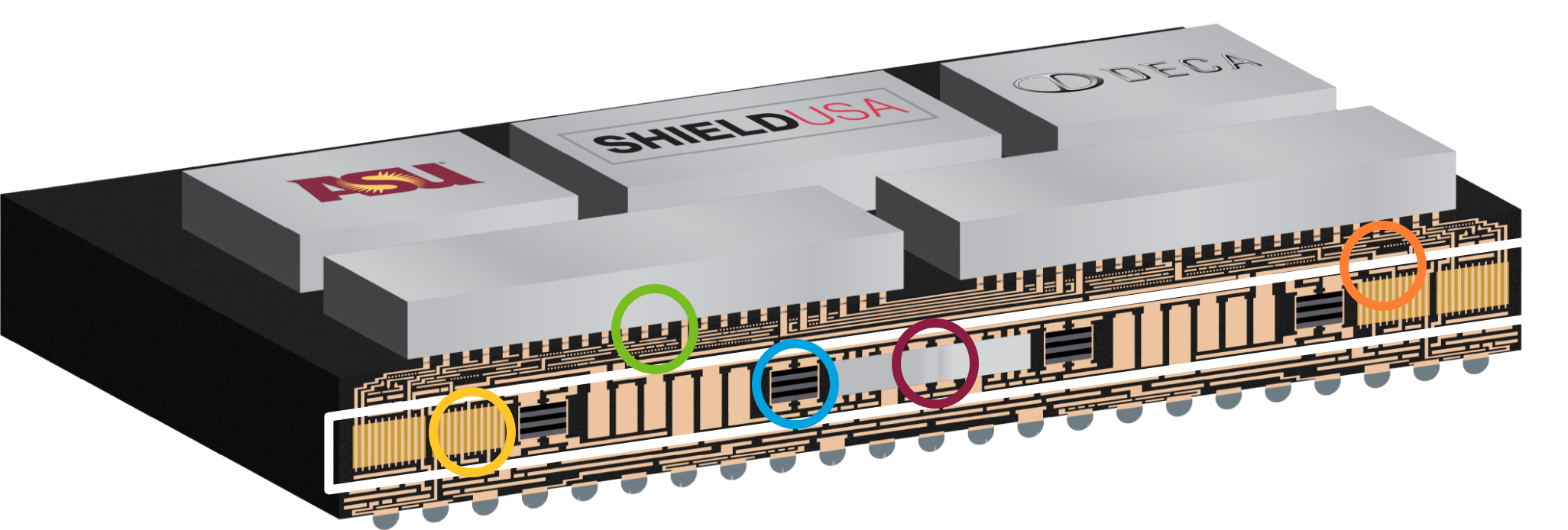

Transforms proven fan-out technology into leap ahead organic substrates

SHIELD USA’s education, training and workforce development programs will support the human capital necessary to establish interconnected foundries and enable a robust foundation for a sustainable domestic pipeline of packaging substrates and materials research and manufacturing for years to come.

This effort draws upon ASU’s Advanced Electronics and Photonics Core Facility, part of ASU’s nationally unique MacroTechnology Works facility, to advance the commercial viability of 300 mm wafer-level and 600 mm panel-level manufacturing. In addition to Deca Technologies, the SHIELD USA team consists of major semiconductor companies, including AMD, Analog Devices, IBM, NXP, SkyWater Technology, Saras Micro, Synopsys, Rogers Corporation and Heidelberg Instruments.

Leap ahead technology

Transforms proven fan-out technology into advanced molded core substrates

Molded fan-out core

High aspect-ratio vertical interconnect blocks (VIBs) ➔ 20 µm pitch through-core

Ultra-fine pitch chiplets and dielets 25 µm ➔ 2 µm pitch

Embedded passives

➔ High density capacitors

➔ Novel inductors for power delivery

Embedded active devices

➔ Power management

➔ RF and III-V devices

➔ Memory IO controllers, etc.

Ultra-high density planarized MDx RDLs 2 µm ➔ 0.5 µm L&S

SHIELD USA executive leadership team

Jason Conrad

SHIELD USA Program Director and SWAP Hub Chief Operating Officer